Uni body design Multiple jet spray with high flow Cleaning Diameter. Spray Balls cip wip SolutionS.

Cip Spray Ball Cleaning Design Holloway

Perfect for pajama functions or just hanging out with your girlfriends.

. Sanitary beer fluid pumps. The CIP Spray ball is ideal for use in the cleaning of fermentation vessels post fermentation cleaning and sanitization of kegs pre and post use among other applications. When considering a custom spray ball there is the possibility that the spray ball will not.

Permanently identified with model and customer identification numbers. Anti-foams and spray ball connections Available CIP flow and pressure Surface finish requirements Directionally Drilled Spray Balls and. Low consumption of liquid operating at low pressure 4.

This particular spray ball is a permanent static mount designed to direct multiple high-velocity jets against the tank wall. One type a fixed-spherical spray ball design is pictured in Figure 1. Between Clean In Place CIP and Wash In Place WIP however the.

Steph has developed this celestial design on quite a few different colors of nails like a base all turning out equally out-of-this-environment. For spray balls 10 selection of cip pumps 10. CIP clean-in-place Process designers specify rotary spray heads when cleaning requires better coverage than static spray balls.

360 CIP rotary tank cleaning spray ball design feature. Spray balls are the main components for cleaning tanks and vessels eg. Cip cycles 11.

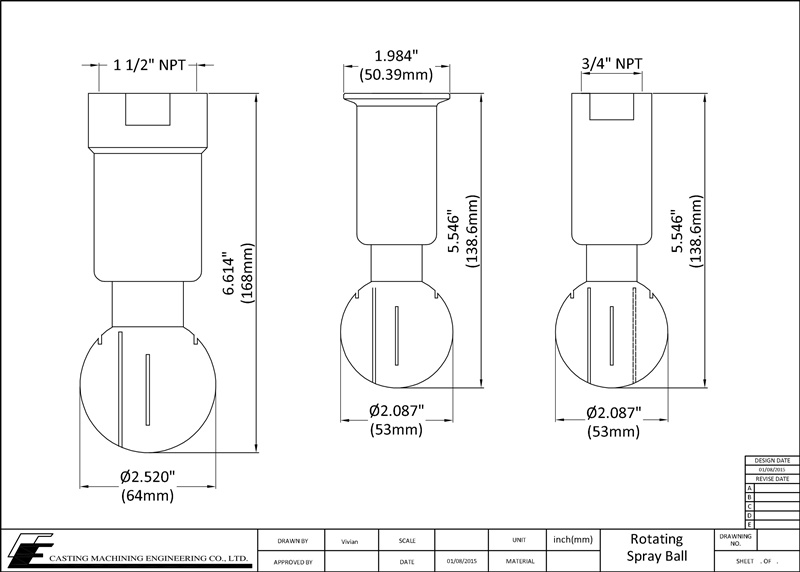

SV-13R series is a rotary CIP Spray Ball for tank cleaning they are mainly used to clean the inside of tanks for food-processing beverage beer and pharmaceutical industries. 360spray 180spray aperture of spray. Cip spray ball design.

Flow ranges from 10 gpm 40 LPM to 80 gpm 300 LPM. Selection of tri clamp fitted dairy distillery beer hoses. Ad Free Shipping Available.

Spray balls as static cleaners are designed for flush cleaning with a high flow rate thus providing powerful flushing at low pressure. 1 Extent of Cleaning The nature of substance to be cleaned from tank should be considered like solubility viscosity nature of powder pigment. Spray ball CIP RETURN PUMP RECOVERED WATER TANK DETERGENT TANK Drain Re-Use System with Recovered Water Tank.

CIP clean in place is a commonly used technique to clean large craft brewing vessels. SS304 SS316 18. Purging of product from.

Ad With an in-house design team we are able to draft nearly any customization. We supply a variety of sizes flow rates and configurations for a broad scope of. 360 degree self-rotating cleaning nozzle cleaning every place of your containers 5.

Double bearing design with excellent rotation effects and better stability and longer life bearing 2. To our entire line of customizable spray devices we are able to design and fabricate custom wands manifolds and other. New pickup delivery customers.

Cleaning equipment left in place during. Before using the CIP Spray Ball rinse out any loose. Spray balls come in many shapes and sizes and have various functions.

Choice of chemicals automation of cip systems 9. Free shipping on qualified orders. 6095 Spray Ball Size Add to Cart CIP clean in place is a commonly used technique to clean large craft brewing vessels.

Made of corrosion-resistant and cleanable materials. Standard spray ball CIP with caustic recovery Steps CIP program Re-use factor Minutes EUR 1 Water rinse 0 10 2625 2 Caustic re-circulation 85 60 2625 3 1 x water rinse 1 cycle 50 5 656 4 8 x sterilant continues re-circulation 90 20 933 5 1 x final rinse 2 cycles 100 6 000 Total per year per fermenter 101 EUR 2529 Five cleanings. Clean in Place CIP.

The ball is elliptical or spherical jet orifice is flat slot shape. Cip design criteria capacities 9. Ad Browse discover thousands of brands.

Storage tanks CIP tanks milk collecting trucks. Rotary spray ball. Fixed spray ball.

At Ss weve taken the same principles used in our pro fermenters and scaled the design down for home brewers to speed up their cleaning process and improve their sanitation practices just like craft breweries. Following some factors should well studied when selecting CIP spray nozzles. Circulation time cip analysis and optimisation 9.

Figure 1 After the fermentor has been drained of its contents attach a ½ barbed fitting to the bottom dump valve. Upto 25 M Type. Ss products have taken the same principles used in our pro fermenters and scaled the design down for home brewers to speed up their cleaning process and improve their sanitation practices just like craft breweries.

As their name suggests rotary spray heads turn while supplying pressurized fans of cleaning solutions or water against the interior surfaces of the tank or vessel during cleaning cycles. Get 10 off your first three orders. Specifically shaped to allow development of various standard and custom spray patterns.

This process is called Clean-In-Place or CIP. Sani-Matic is 3-A certified for its standard spray ball design when used with a slip collar or butt weld. The process plant 10 re-use of cleaning solutions 11.

Hygienic self-cleaning and self- draining design which allows spray devices to be left in place in product-contact zones. Free easy returns on millions of items. Read customer reviews find best sellers.

CIP Spray Ball for Chronical Fermenters. The infant colors glimpse remarkable and clean up on this bit of nail artwork. Self-cleaning self-lubricating design 3.

Self-cleaning and self-lubrication design when working it also cleans and lubricates the rotating nozzle itself which guarantees.

Static Spray Balls Sani Matic Inc

Static Spray Balls Sani Matic Inc

Rotating Spray Ball Cip Tri Clamp 2 Inch X 2 5 Ball Ss304

Spray Ball Types How To Select The Right One For Your Process

Stainless Steel Cip Rotating Spray Ball

9 Vessel Design Factors That Dramatically Affect Cip Performance Lee Industries

0 komentar

Posting Komentar